3d Printing's Future: Trends Forming The Sector

페이지 정보

작성자 Omer

조회 4회 작성일 24-02-27 11:32

조회 4회 작성일 24-02-27 11:32

본문

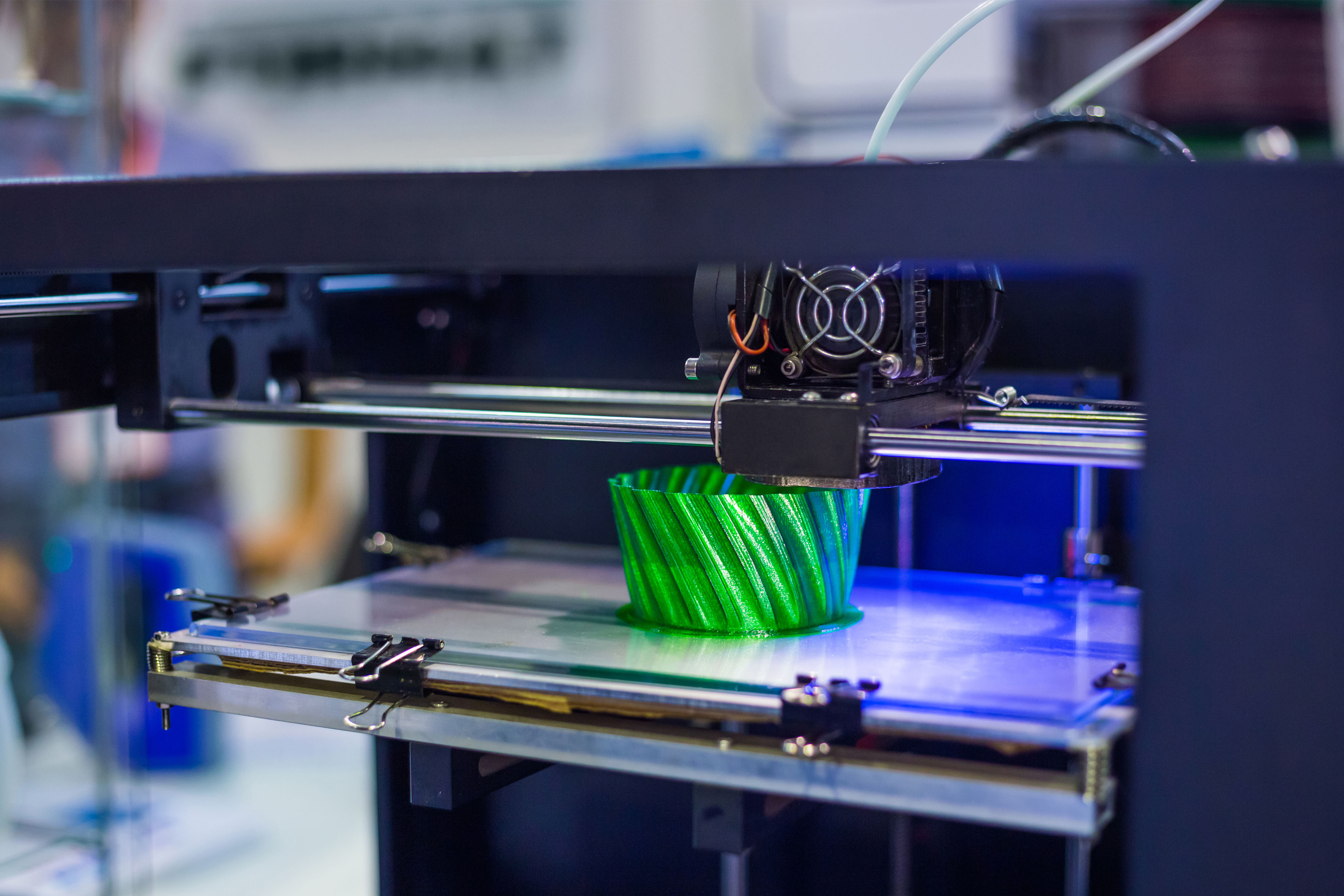

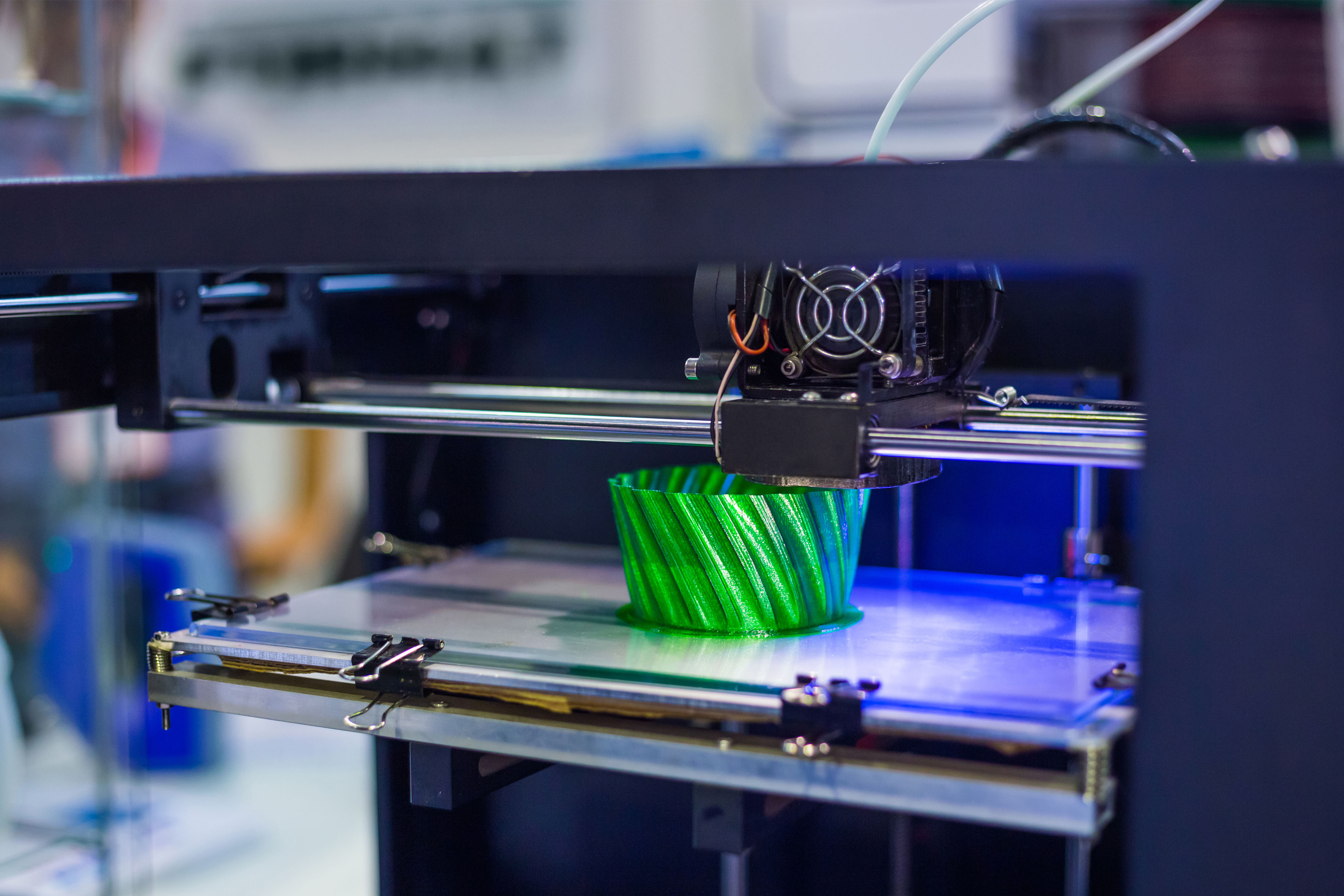

Over the following decade, I forecast that full-color 3D printing will be picked up by little to medium-sized companies, as printers such as our 3DUJ-2207 become more economical in addition to even more comfortably sized for a workplace.

We have actually made terrific flexi toys with it, but the useful slim walled air duster revealed over in Translucent Purple is a favorite. Matterhackers' transparent TPUs are glossy as well as sparkly, which suggests anything you print with them will certainly be fun to take a look at ask well as play with. We have actually made a fantastic phone situation with it and of course-- the phone has actually survived a number of drops. Its coast firmness is normal for Window Clings TPU at 95A, suggesting it is soft and also adaptable like a flip-flop or perhaps a tire. Naturally this all relies on how thick you make the walls as well as infill. Our example print made use of 2 wall surfaces and also 10% infill, transforming the Thwack Inculcate more of a Clown Hammer.

We have actually made terrific flexi toys with it, but the useful slim walled air duster revealed over in Translucent Purple is a favorite. Matterhackers' transparent TPUs are glossy as well as sparkly, which suggests anything you print with them will certainly be fun to take a look at ask well as play with. We have actually made a fantastic phone situation with it and of course-- the phone has actually survived a number of drops. Its coast firmness is normal for Window Clings TPU at 95A, suggesting it is soft and also adaptable like a flip-flop or perhaps a tire. Naturally this all relies on how thick you make the walls as well as infill. Our example print made use of 2 wall surfaces and also 10% infill, transforming the Thwack Inculcate more of a Clown Hammer.

That's bearable for a hobbyist, but comes to be a great void of costs on a large scale. The approaching year may be instead productive in terms of developments targeted at lowering printing mistakes. There will certainly be a great deal of initiative from market players to make 3D printing less wasteful. Over the in 2014, we have actually seen big organizations making use of additive in their industrial manufacturing, not just for tooling, but also for mass market 'buy-in'.

Moreover, the AM post-processing stage, which has usually been a manual procedure, is becoming much more digitised. On the hardware side, business are releasing brand-new, incorporated production units, which incorporate robotics and smart manufacturing facility concepts to automate numerous steps of the production operations. Within this duration, end-use components are anticipated to end up being the largest income possibility.

One of the extra significant searchings for in our survey was that 83% of respondents claimed 3D printing has helped them save substantial prices in their manufacturing pipeline. Reasons for this consist of lower prototyping expenses as contrasted to injection molding, for example, which calls for a new device for every version. Sometimes, in-house printing results in reduce prices, too, VOCs (volatile organic compounds) though commercial grade printers call for a considerable upfront outlay of funds. It's time to supply on the pledges made to investors and verify business designs for practical applications. A particularly solid fad is making use of easier and cheaper devices for manufacturing.

I believe we'll start to see a change, with a shakeout amongst weaker 'me too' offerings as they fail to obtain sufficient momentum to stay in the market. Of course, this will certainly result in a tactical combination across the sector, but this is more of a long-run pattern, although we can see it beginning and establishing in 2023. There has been a significant amount of r & d in creating new products that can be made use of in additive manufacturing, and these materials will certainly continue to increase and improve. From metals, porcelains, polymers, and materials with stiff, flexible, and elastomeric attributes and enhanced, e.g. mechanical residential properties and thermal resistance. Advancements such as IoT and I4.0 only rise the justification to integrate additive manufacturing as an added mainstream manufacturing method, occasionally a replacement to, yet in most cases enhancing standard production methods. Additive production is mosting likely to be our only remedy for exactly how we produce products in the future, consisting of medical care.

TPU. TPU (Thermoplastic polyurethane) is most well known for its adaptability, which is what makes this 3D printing material so strong. In addition to being versatile, TPU is also highly long lasting, with solid resistance to impact, wear and tear, chemicals, and abrasion.

This method integrates the benefits of AM with those of injection molding (product adaptability and premium quality with very little post-processing). Likewise, the adoption of inkjet as a production modern technology in the many finishing applications presently performed by analogue methods, will certainly provide several benefits, from manufacturing performances to even more lasting manufacturing processes. Additive production will certainly can processing extra presently used conventional industrial materials and possibly, some proprietary materials made for additive manufacturing will certainly be qualified to be made use of for products producing. Things is that we, Carima have created the C-CAT, which is the globe's fastest 3D printing technology that boosted performance by at least 20 times contrasted to the existing DLP modern technology, as one of the worldwide 3D printer manufacturers. We intend to update it and market new 3D printers with that said modern technology in the next 1-2 years. For that reason, to target standard manufacturing methods, the development of distinguished 3D printing modern technology is undoubtedly required to be ready urgently, and it is most likely that the AM/3DP market will be preserved for the next decade.

Drug governing agencies like FDA and EMA will comply with the means initiate by the UK agency managing 3D printing for Point of Care manufacturing. 3D printing will certainly continue to control as a prototyping and tooling service, its killer application. And as even more designers explore what 3D printing can give their businesses, more will make use of the full degree of solutions from on-line manufacturing platforms, like Centers, for VOCs (volatile organic compounds) their 3D printing needs. Dependency on highly-trained labor forces throughout the full manufacturing lifecycle will remain to be an obstacle regardless of broadened workforce training and greater automation of preproduction processes. Educating for office, design, and manufacturing personnel, along with broadened process automation, will certainly add to bigger AM use beyond prototyping, bridge, and high-value markets.

Apple Ios 172 Apple Iphone Software Application Release: Should You Upgrade?

In addition to a high level of automation, this includes innovative powder recovery. Our company believe that Solukon prepares to resolve current difficulties and we will certainly remain to establish our automated powder recovery systems to attend to future demands also. Although the quality and accuracy compared to subtractive manufacturing can be a lot higher, the cost and waiting time are likewise high. For these factors, AM was not able to have a large use in the majority of the industry. With several years of growth, AM will end up being a growing number of crucial and mature than subtractive production in the manufacturing industry in a years, not simply being an encouraging method for the manufacturing industry like it utilized to be.

We have actually made terrific flexi toys with it, but the useful slim walled air duster revealed over in Translucent Purple is a favorite. Matterhackers' transparent TPUs are glossy as well as sparkly, which suggests anything you print with them will certainly be fun to take a look at ask well as play with. We have actually made a fantastic phone situation with it and of course-- the phone has actually survived a number of drops. Its coast firmness is normal for Window Clings TPU at 95A, suggesting it is soft and also adaptable like a flip-flop or perhaps a tire. Naturally this all relies on how thick you make the walls as well as infill. Our example print made use of 2 wall surfaces and also 10% infill, transforming the Thwack Inculcate more of a Clown Hammer.

We have actually made terrific flexi toys with it, but the useful slim walled air duster revealed over in Translucent Purple is a favorite. Matterhackers' transparent TPUs are glossy as well as sparkly, which suggests anything you print with them will certainly be fun to take a look at ask well as play with. We have actually made a fantastic phone situation with it and of course-- the phone has actually survived a number of drops. Its coast firmness is normal for Window Clings TPU at 95A, suggesting it is soft and also adaptable like a flip-flop or perhaps a tire. Naturally this all relies on how thick you make the walls as well as infill. Our example print made use of 2 wall surfaces and also 10% infill, transforming the Thwack Inculcate more of a Clown Hammer.That's bearable for a hobbyist, but comes to be a great void of costs on a large scale. The approaching year may be instead productive in terms of developments targeted at lowering printing mistakes. There will certainly be a great deal of initiative from market players to make 3D printing less wasteful. Over the in 2014, we have actually seen big organizations making use of additive in their industrial manufacturing, not just for tooling, but also for mass market 'buy-in'.

Moreover, the AM post-processing stage, which has usually been a manual procedure, is becoming much more digitised. On the hardware side, business are releasing brand-new, incorporated production units, which incorporate robotics and smart manufacturing facility concepts to automate numerous steps of the production operations. Within this duration, end-use components are anticipated to end up being the largest income possibility.

One of the extra significant searchings for in our survey was that 83% of respondents claimed 3D printing has helped them save substantial prices in their manufacturing pipeline. Reasons for this consist of lower prototyping expenses as contrasted to injection molding, for example, which calls for a new device for every version. Sometimes, in-house printing results in reduce prices, too, VOCs (volatile organic compounds) though commercial grade printers call for a considerable upfront outlay of funds. It's time to supply on the pledges made to investors and verify business designs for practical applications. A particularly solid fad is making use of easier and cheaper devices for manufacturing.

I believe we'll start to see a change, with a shakeout amongst weaker 'me too' offerings as they fail to obtain sufficient momentum to stay in the market. Of course, this will certainly result in a tactical combination across the sector, but this is more of a long-run pattern, although we can see it beginning and establishing in 2023. There has been a significant amount of r & d in creating new products that can be made use of in additive manufacturing, and these materials will certainly continue to increase and improve. From metals, porcelains, polymers, and materials with stiff, flexible, and elastomeric attributes and enhanced, e.g. mechanical residential properties and thermal resistance. Advancements such as IoT and I4.0 only rise the justification to integrate additive manufacturing as an added mainstream manufacturing method, occasionally a replacement to, yet in most cases enhancing standard production methods. Additive production is mosting likely to be our only remedy for exactly how we produce products in the future, consisting of medical care.

TPU. TPU (Thermoplastic polyurethane) is most well known for its adaptability, which is what makes this 3D printing material so strong. In addition to being versatile, TPU is also highly long lasting, with solid resistance to impact, wear and tear, chemicals, and abrasion.

This method integrates the benefits of AM with those of injection molding (product adaptability and premium quality with very little post-processing). Likewise, the adoption of inkjet as a production modern technology in the many finishing applications presently performed by analogue methods, will certainly provide several benefits, from manufacturing performances to even more lasting manufacturing processes. Additive production will certainly can processing extra presently used conventional industrial materials and possibly, some proprietary materials made for additive manufacturing will certainly be qualified to be made use of for products producing. Things is that we, Carima have created the C-CAT, which is the globe's fastest 3D printing technology that boosted performance by at least 20 times contrasted to the existing DLP modern technology, as one of the worldwide 3D printer manufacturers. We intend to update it and market new 3D printers with that said modern technology in the next 1-2 years. For that reason, to target standard manufacturing methods, the development of distinguished 3D printing modern technology is undoubtedly required to be ready urgently, and it is most likely that the AM/3DP market will be preserved for the next decade.

Drug governing agencies like FDA and EMA will comply with the means initiate by the UK agency managing 3D printing for Point of Care manufacturing. 3D printing will certainly continue to control as a prototyping and tooling service, its killer application. And as even more designers explore what 3D printing can give their businesses, more will make use of the full degree of solutions from on-line manufacturing platforms, like Centers, for VOCs (volatile organic compounds) their 3D printing needs. Dependency on highly-trained labor forces throughout the full manufacturing lifecycle will remain to be an obstacle regardless of broadened workforce training and greater automation of preproduction processes. Educating for office, design, and manufacturing personnel, along with broadened process automation, will certainly add to bigger AM use beyond prototyping, bridge, and high-value markets.

Apple Ios 172 Apple Iphone Software Application Release: Should You Upgrade?

In addition to a high level of automation, this includes innovative powder recovery. Our company believe that Solukon prepares to resolve current difficulties and we will certainly remain to establish our automated powder recovery systems to attend to future demands also. Although the quality and accuracy compared to subtractive manufacturing can be a lot higher, the cost and waiting time are likewise high. For these factors, AM was not able to have a large use in the majority of the industry. With several years of growth, AM will end up being a growing number of crucial and mature than subtractive production in the manufacturing industry in a years, not simply being an encouraging method for the manufacturing industry like it utilized to be.

- 이전글udzqvuoe 24.02.27

- 다음글What You Can Use A Weekly Car Locksmith Near Me Project Can Change Your Life 24.02.27